| Model |

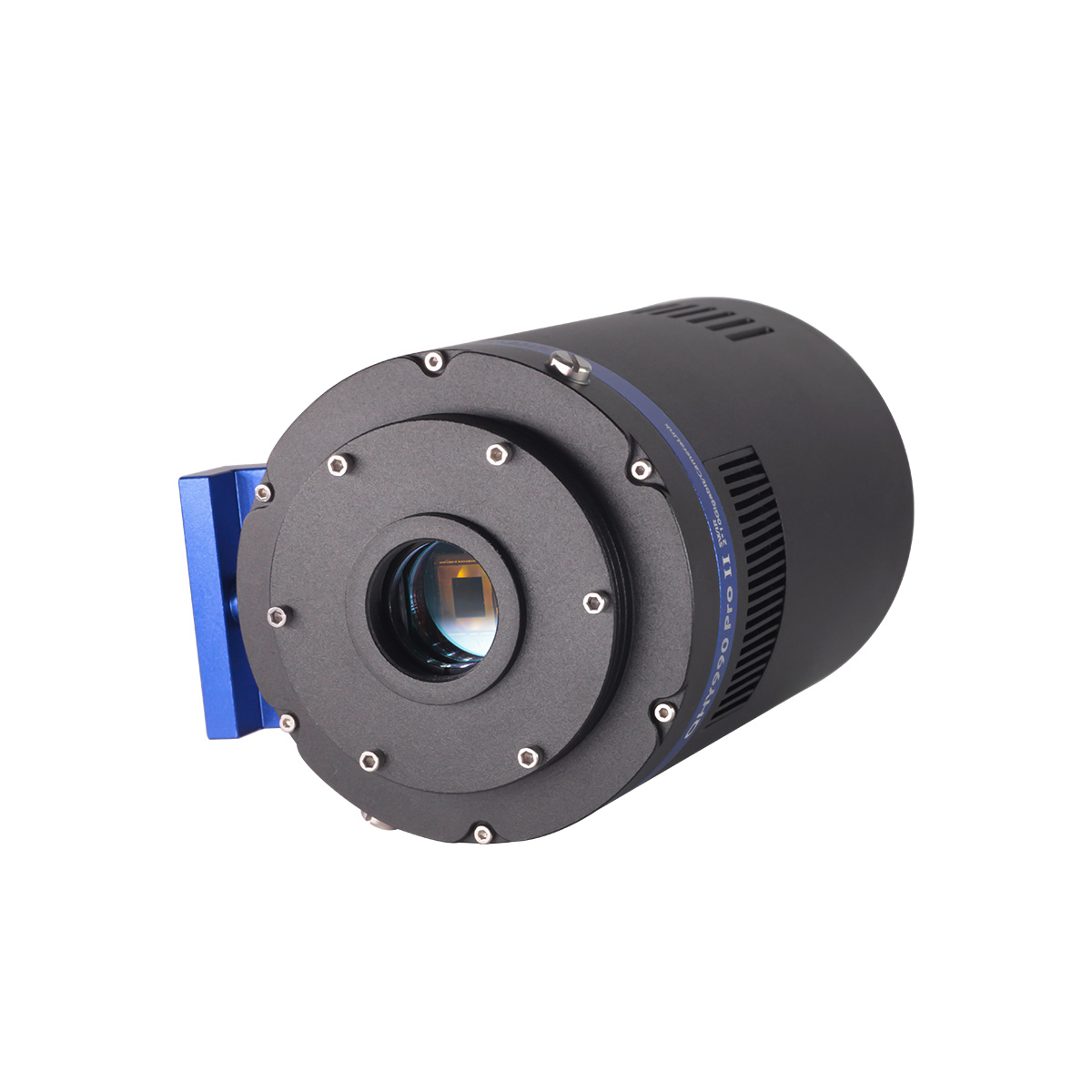

QHY990 |

QHY990Pro II |

QHY991 |

| Image Sensor |

Sony IMX990 InGaAs |

Sony IMX990 InGaAs |

Sony IMX991 InGaAs |

| Sensor Type |

Mono Only |

Mono Only |

Mono Only |

| Pixel Size |

5.0μm*5.0μm |

5.0μm*5.0μm |

5.0μm*5.0μm |

| Effective Pixels |

1.3 Megapixels |

1.3 Megapixels |

0.4 Megapixels |

| Effective Image Area |

1/2 inch |

1/2 inch |

1/4 inch |

| Effective Pixel Area |

1296*1032 |

1296*1032 |

656*520 |

| Total Pixel Area |

1392*1052 |

1392*1052 |

752*520 |

| A/D |

12-bit A/D |

12-bit A/D |

12-bit A/D |

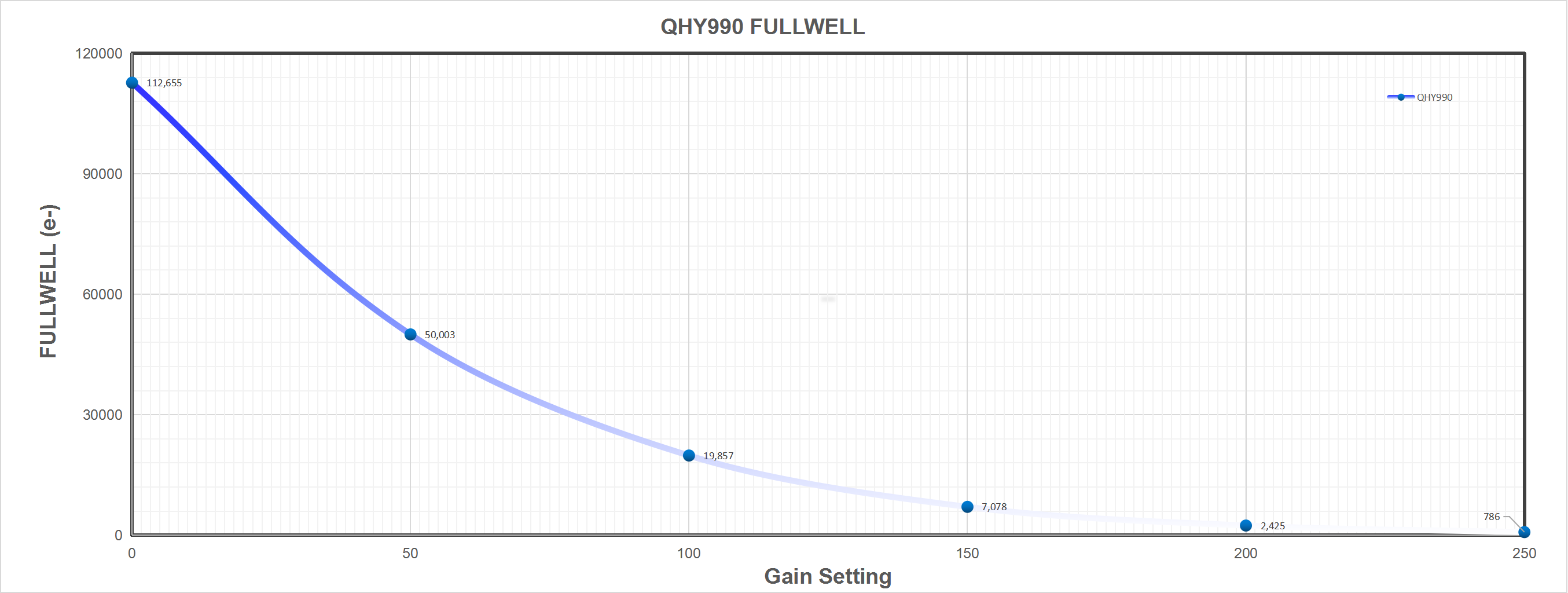

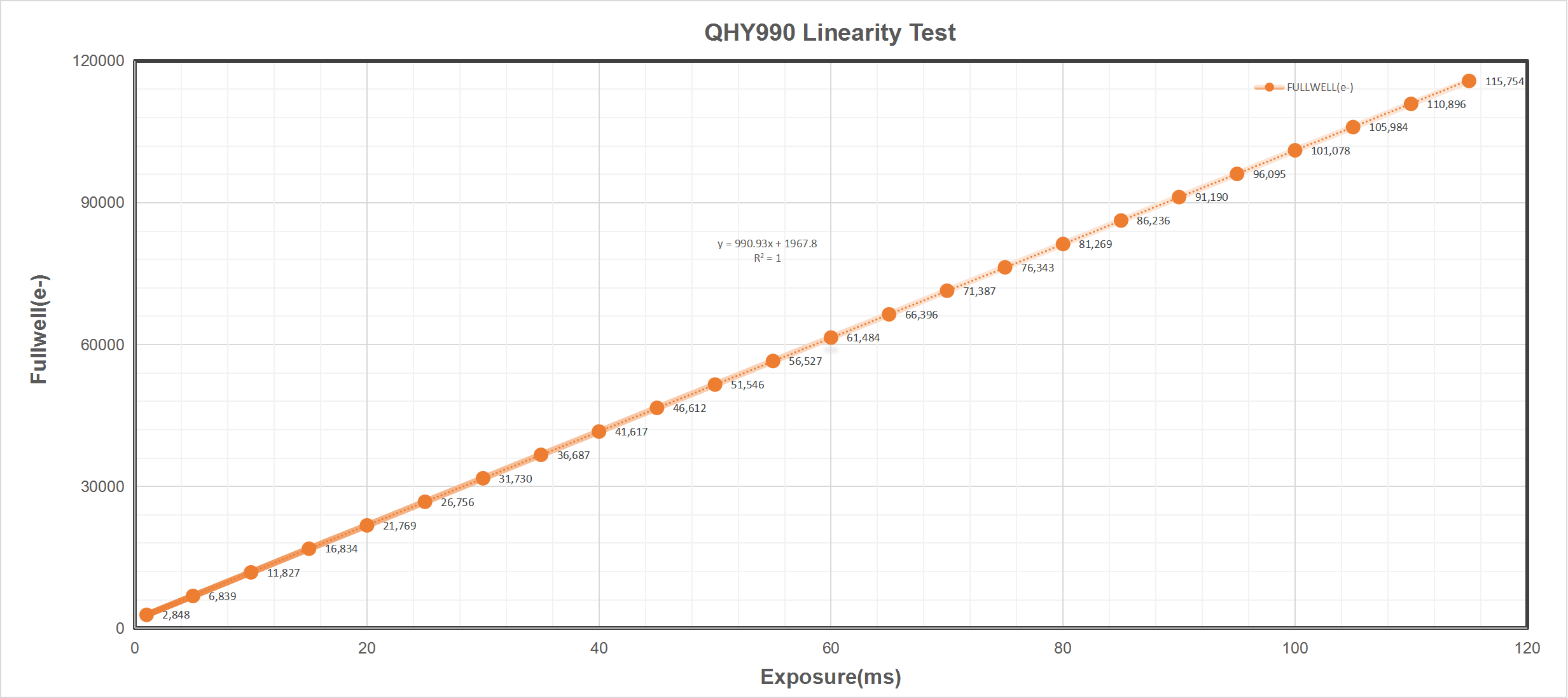

| Full Well Capacity (1×1, 2×2, 3×3)

|

Typical 112ke- |

Typical 112ke- |

Typical 112ke- |

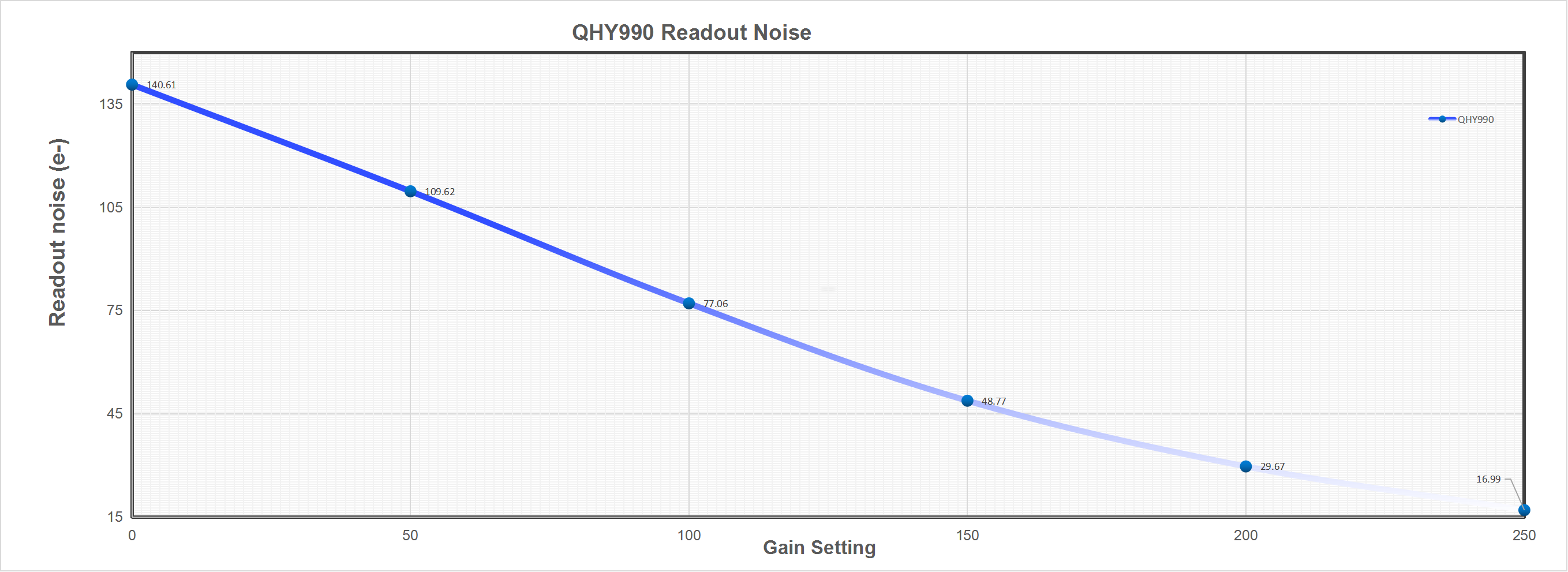

| Read Noise |

The measured data is after Bias Frame FPN calibration.

Typical 150e- at lowest gain

Typical 50e- at a middle gain

Typical 20e- at high gain |

The measured data is after Bias Frame FPN calibration.

Typical 150 e- at lowest gain

Typical 50e- at a middle gain

Typical 20e- at high gain |

The measured data is after Bias Frame FPN calibration.

Typical 150 e- at lowest gain

Typical 50e- at a middle gain

Typical 20e- at high gain |

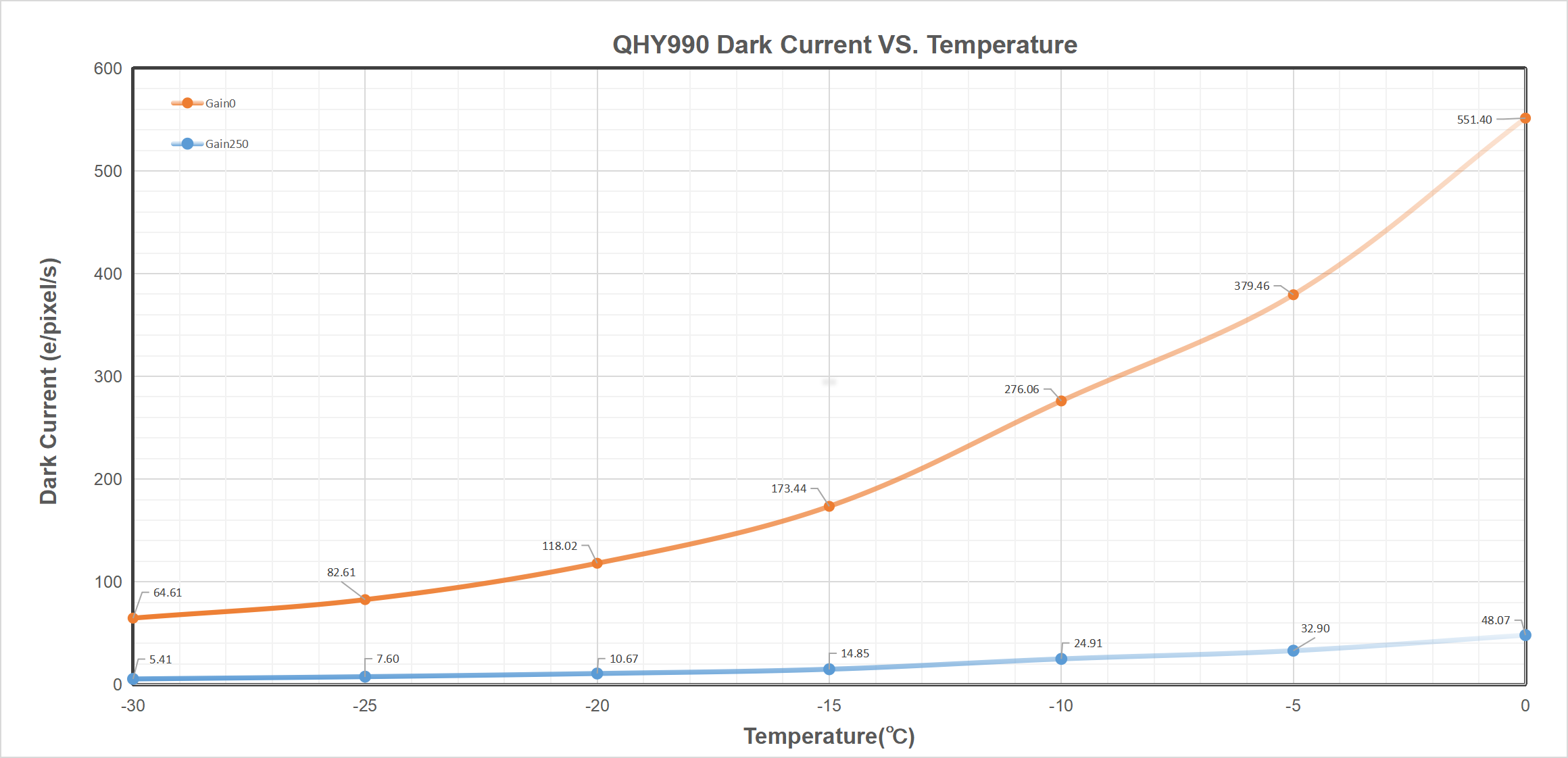

| Dark Current |

64.6e-/pixel/sec @-30℃ Gain0

5.41e-/pixel/sec @-30℃ Gain250

|

64.6e-/pixel/sec @-30℃ Gain0

5.41e-/pixel/sec @-30℃ Gain250

|

64.6e-/pixel/sec @-30℃ Gain0

5.41e-/pixel/sec @-30℃ Gain250

|

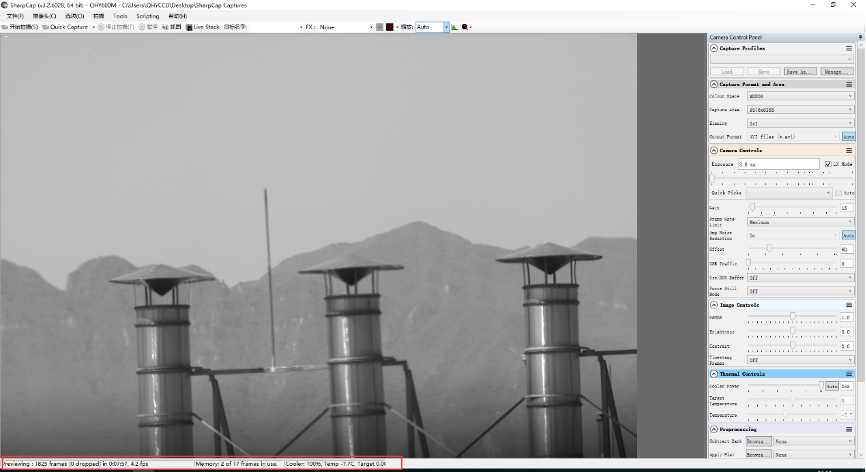

| Exposure Time Range |

30μs-300sec |

30μs-300sec |

30μs-300sec |

| Shutter Type |

Electronic Global Shutter |

Electronic Global Shutter |

Electronic Global Shutter |

| Computer Interface |

USB3.0 |

1*USB3.0 Interface

2*10Gigabit Fiber Interfaces

2*CameraLink Interfaces (Pro II Version Only) |

USB3.0 |

| Filter Wheel Interface

|

4PIN QHYCCD CFW Port |

4PIN QHYCCD CFW Port |

4PIN QHYCCD CFW Port |

| Trigger Port |

One Hardware Trig-In Socket (RCA type).Opto-isolated |

One Hardware Trig-In Socket (RCA type).Opto-isolated |

One Hardware Trig-In Socket (RCA type).Opto-isolated |

| Full Frame Rates |

USB3.0:

66FPS@8bit

66FPS@16bit |

USB3.0:

66FPS@8bit

66FPS@16bit

PCIE Mode:

66FPS@8bit

66FPS@16bit

CameraLink

TBA |

USB3.0:

123FPS@8bit

123FPS@16bit |

| ROI Frame Rates

|

USB3.0:

768lines, 81.8FPS@8BIT, 81.8FPS@16BIT

480lines, 123.9FPS@8bit, 123.9FPS@16bit |

USB3.0:

768lines, 81.8FPS@8BIT, 81.8FPS@16BIT

480lines, 123.9FPS@8bit, 123.9FPS@16bit

PCIE Mode:

768lines, 81.8FPS@8BIT, 81.8FPS@16BIT

480lines, 123.9FPS@8bit, 123.9FPS@16bit

CameraLink

TBA |

USB3.0:

480lines, 132FPS@8BIT, 132FPS@16BIT

256lines, 230FPS@8BIT, 230FPS@16BIT |

| Built-in Image Buffer |

128MB DDR2 Memory Buffer |

128MB DDR2 Memory Buffer |

128MB DDR2 Memory Buffer |

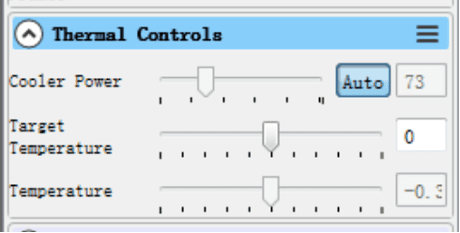

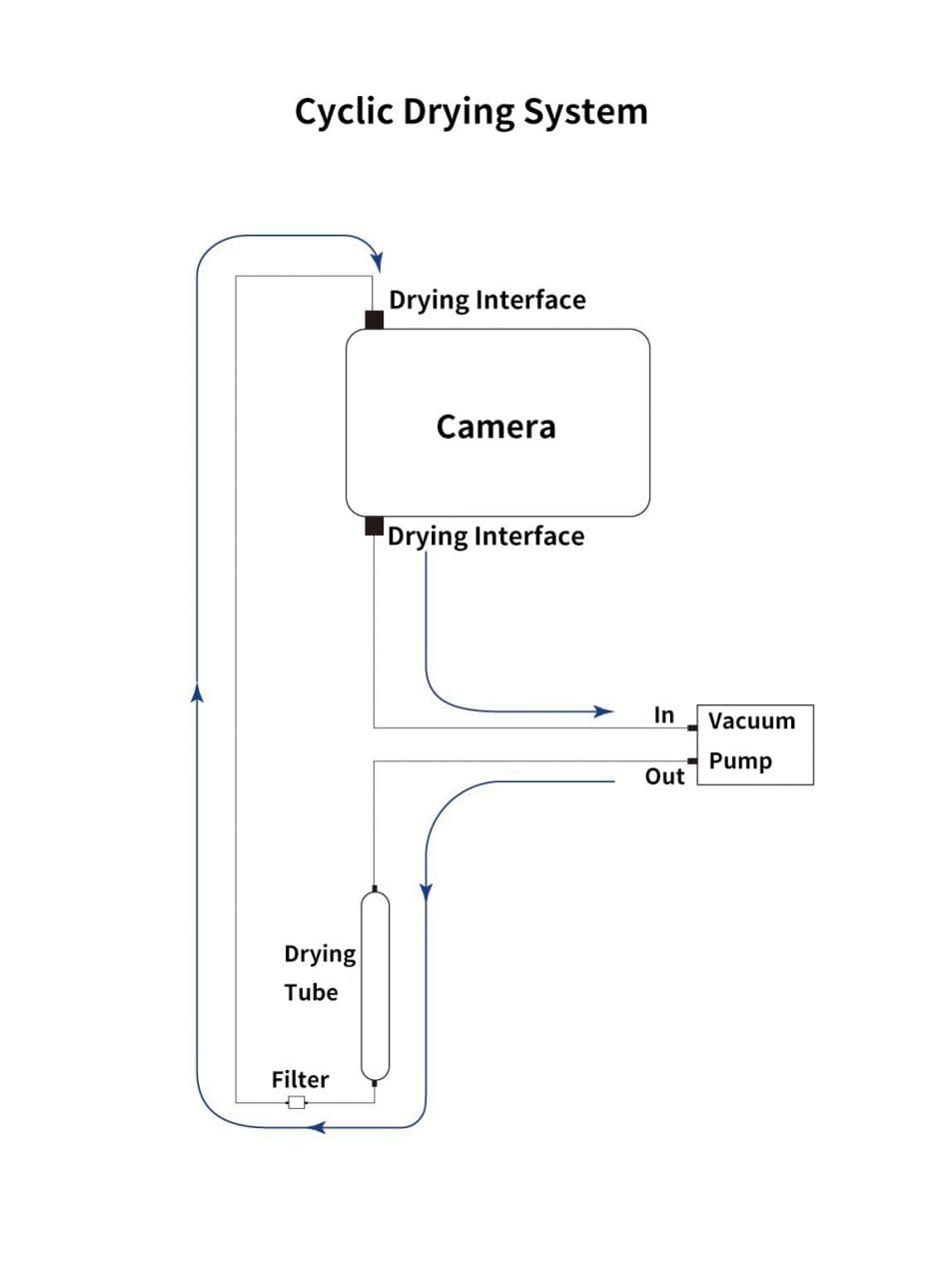

| Air Cooling System |

Dual Stage TEC cooler:

-35℃ below ambient (Test temperature 20℃) |

Dual Stage TEC cooler:

-35℃ below ambient (Test temperature 20℃) |

|

| Liquid Cooling |

|

Available.

-45℃ below ambient with normal water; -60℃ to -80℃ with cold liquid. |

|

| Recommended Flow Rates |

|

1.6ml/s |

|

| Anti-Dew Heater |

Available |

Available |

Available |

| Firmware/FPGA remote Upgrade |

Available via Camera USB port |

Available via Camera USB port |

Available via Camera USB port |

| Optic Window Type |

AR+AR High Quality Multi-Layer Anti-Reflection Coating |

AR+AR High Quality Multi-Layer Anti-Reflection Coating |

AR+AR High Quality Multi-Layer Anti-Reflection Coating |

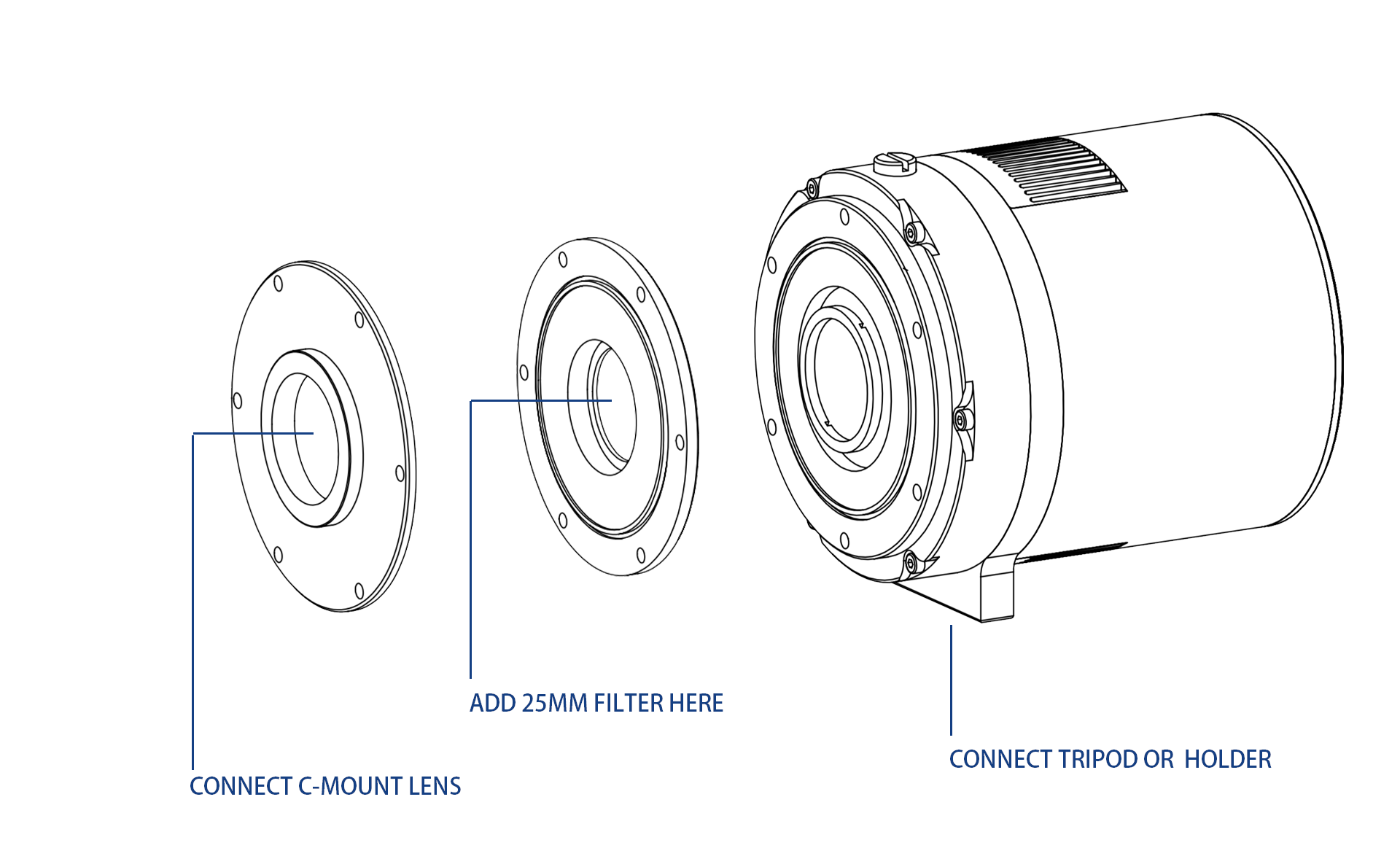

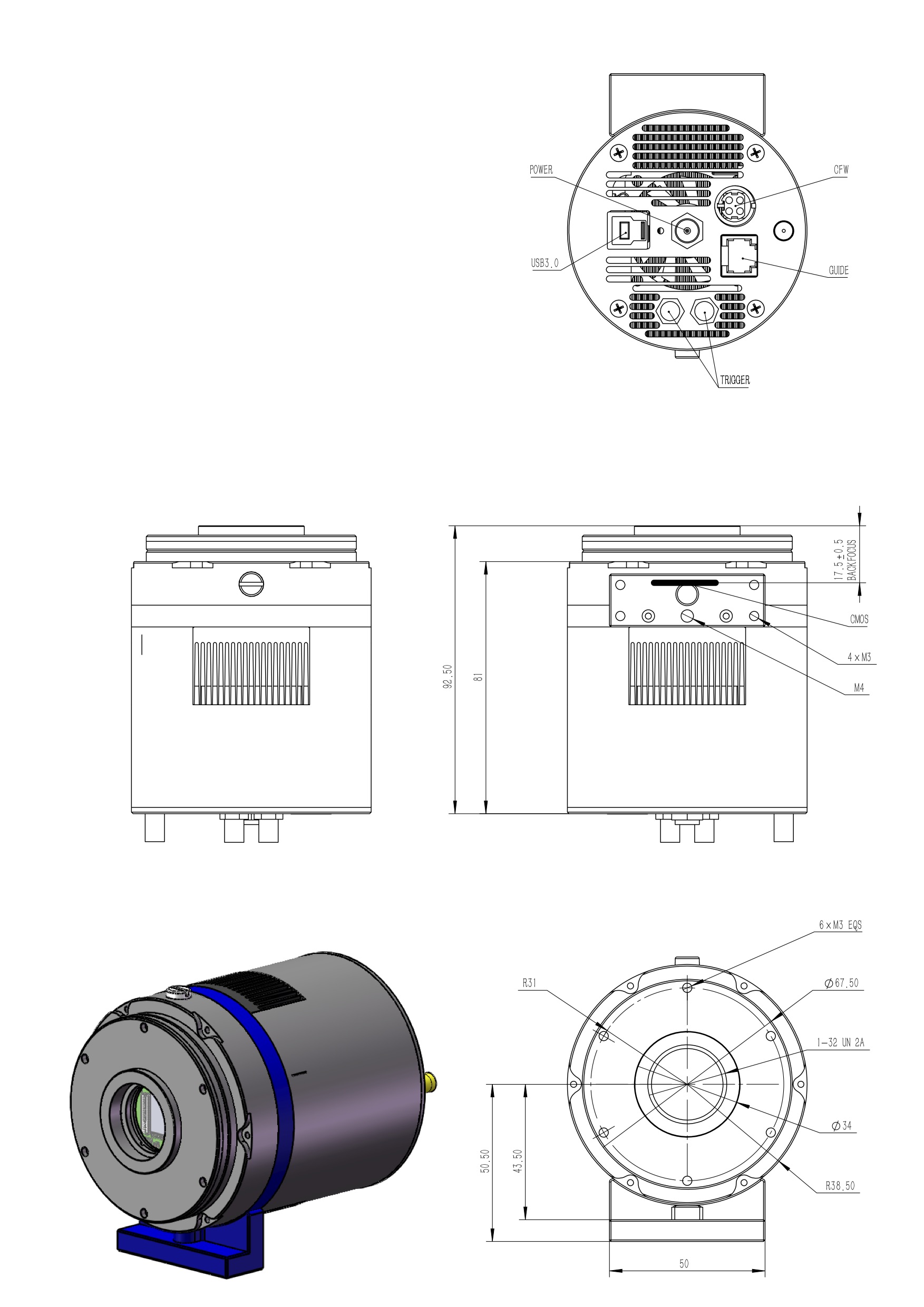

| Back Focal Length |

12.5mm |

12.5mm |

12.5mm |

| Adapters |

Support C_Mount,1.25inch (with adapter)

Support D=25mm and D=25.4mm filter |

Support C_Mount,1.25inch (with adapter)

Support D=25mm and D=25.4mm filter |

Support C_Mount,1.25inch (with adapter)

Support D=25mm and D=25.4mm filter |

| Weight |

520g |

About 1kg |

520g |

| Power |

40W/100%

26.5W/50%

10W/0% |

40W/100%

26.5W/50%

10W/0% |

24W/100%

10W/50%

1W/0% |