| ROI Frame Rates

|

USB3.0:

2048lines, 10.2FPS@8bit, 5.1FPS@16bit

1080lines, 18.5FPS@8bit, 9.8FPS@16bit

768lines, 25.3FPS@8bit, 12.9FPS@16bit

480lines, 36.6FPS@8bit, 19.2FPS@16bit

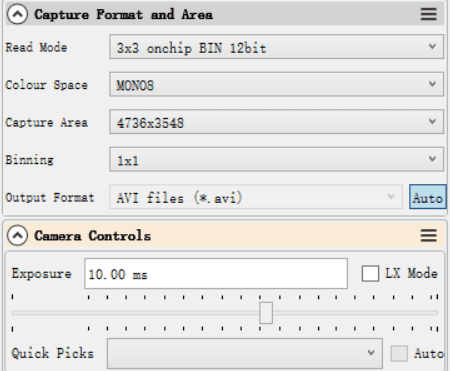

3×3 Onchip Binning 12bit:

3548lines, 20.2FPS@8bit, 10.1FPS@16bit

1080lines, 62.6FPS@8bit, 32.8FPS@16bit

768lines, 84.8FPS@8bit, 43.2FPS@16bit

480lines, 131FPS@8bit, 68.8FPS@16bit

PCIE Mode:

2048lines, 10.2FPS@8bit, 5.1FPS@16bit

1080lines, 18.5FPS@8bit, 9.8FPS@16bit

768lines, 25.3FPS@8bit, 12.9FPS@16bit

480lines, 36.6FPS@8bit, 19.2FPS@16bit

PCIE 3×3 Onchip Binning 12bit:

3548lines, 20.2FPS@8bit, 12.6FPS@16bit

1080lines, 62.6FPS@8bit, 43.6FPS@16bit

768lines, 84.8FPS@8bit, 43.2FPS@16bit

480lines, 131FPS@8bit, 102FPS@16bit |

USB3.0:

2048lines, 10.8FPS@8bit, 6.1FPS@16bit

1080lines, 19.5FPS@8bit, 10.8FPS@16bit

768lines, 26.1FPS@8bit, 14.7FPS@16bit

480lines, 37.1FPS@8bit, 20.5FPS@16bit

PCIE Mode:

2048lines, 10.9FPS@8bit, 9.2FPS@16bit

1080lines, 19.7FPS@8bit, 18.6FPS@16bit

768lines, 25.8FPS@8bit, 24.6FPS@16bit

480lines, 36.6FPS@8bit, 35.5FPS@16bit |

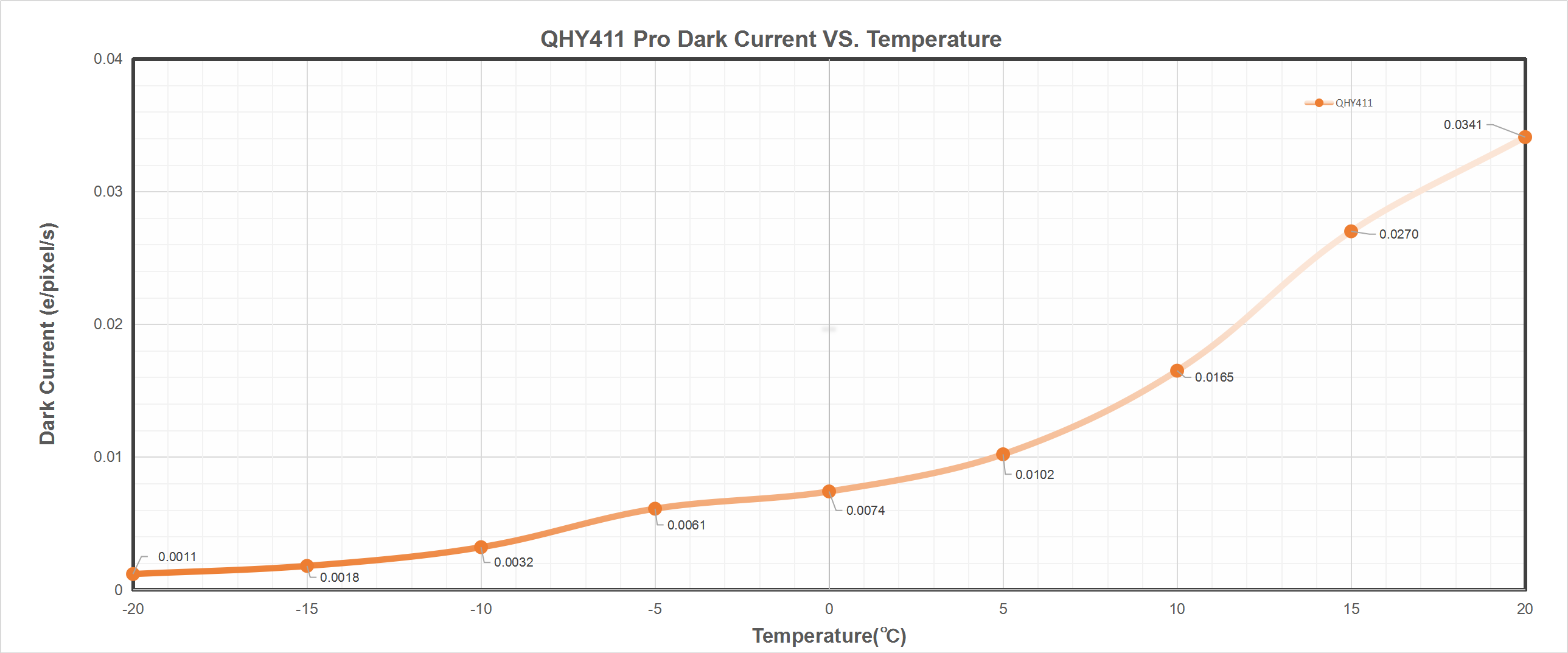

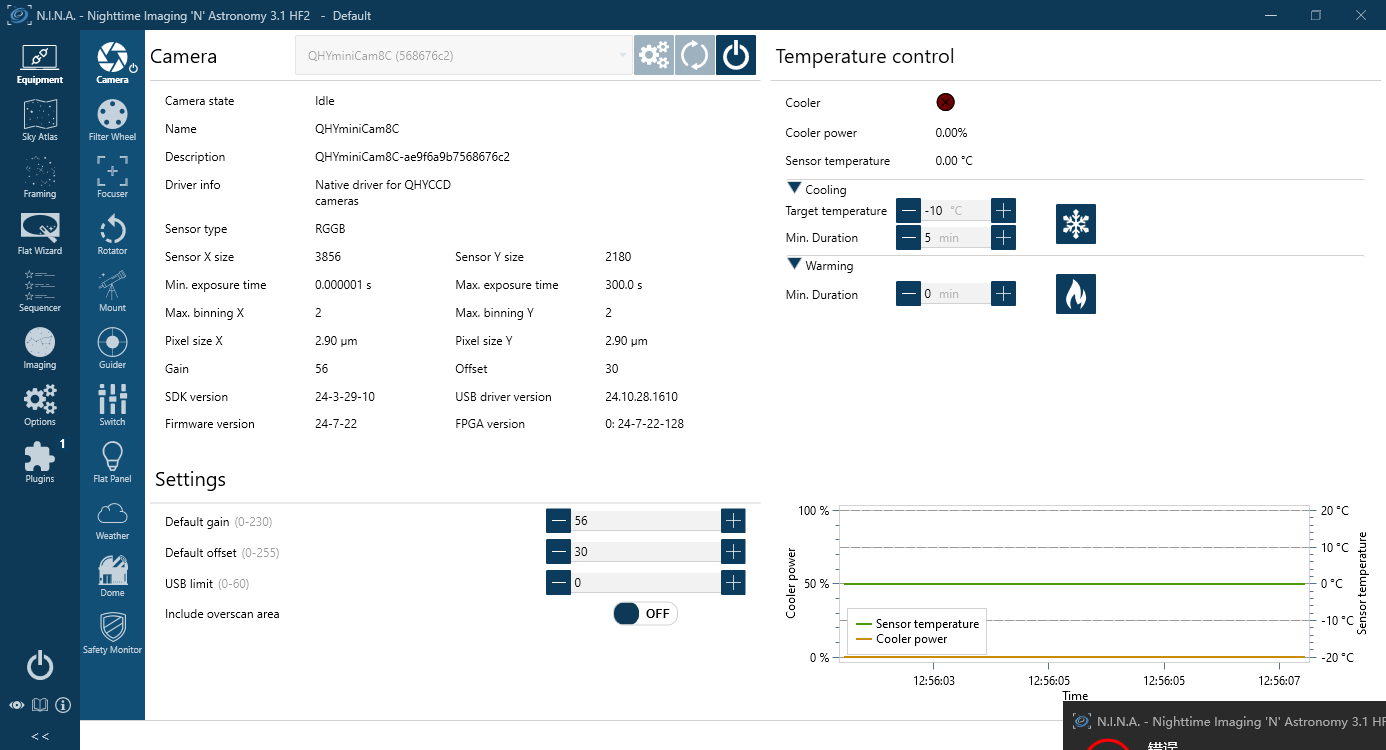

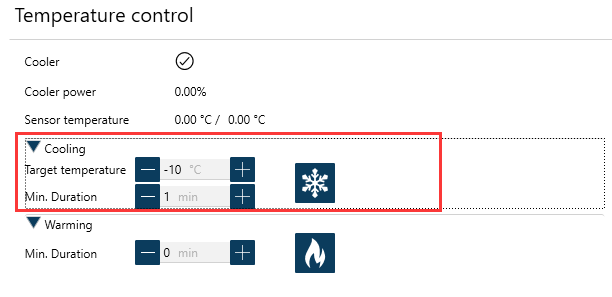

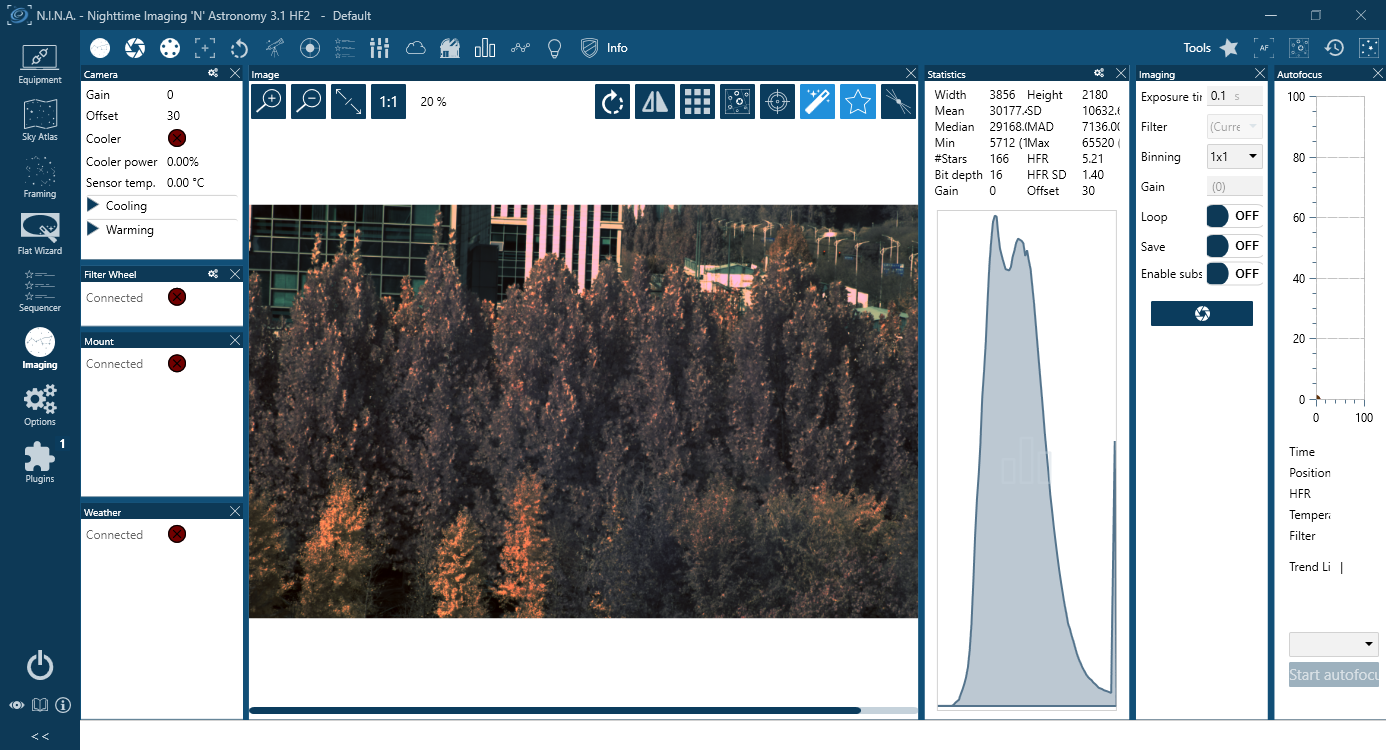

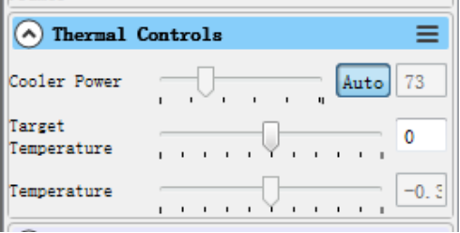

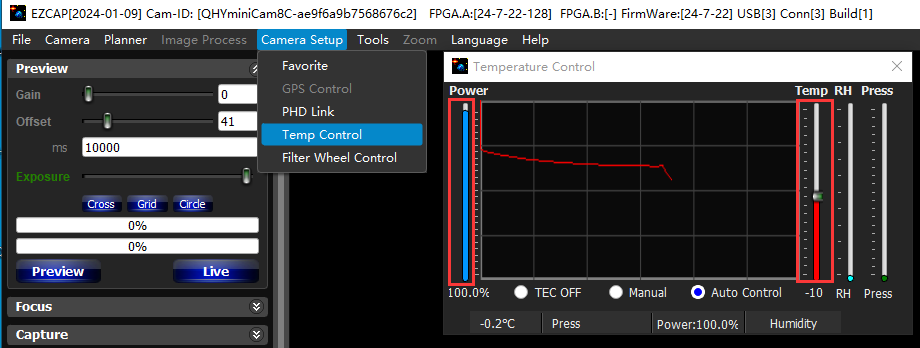

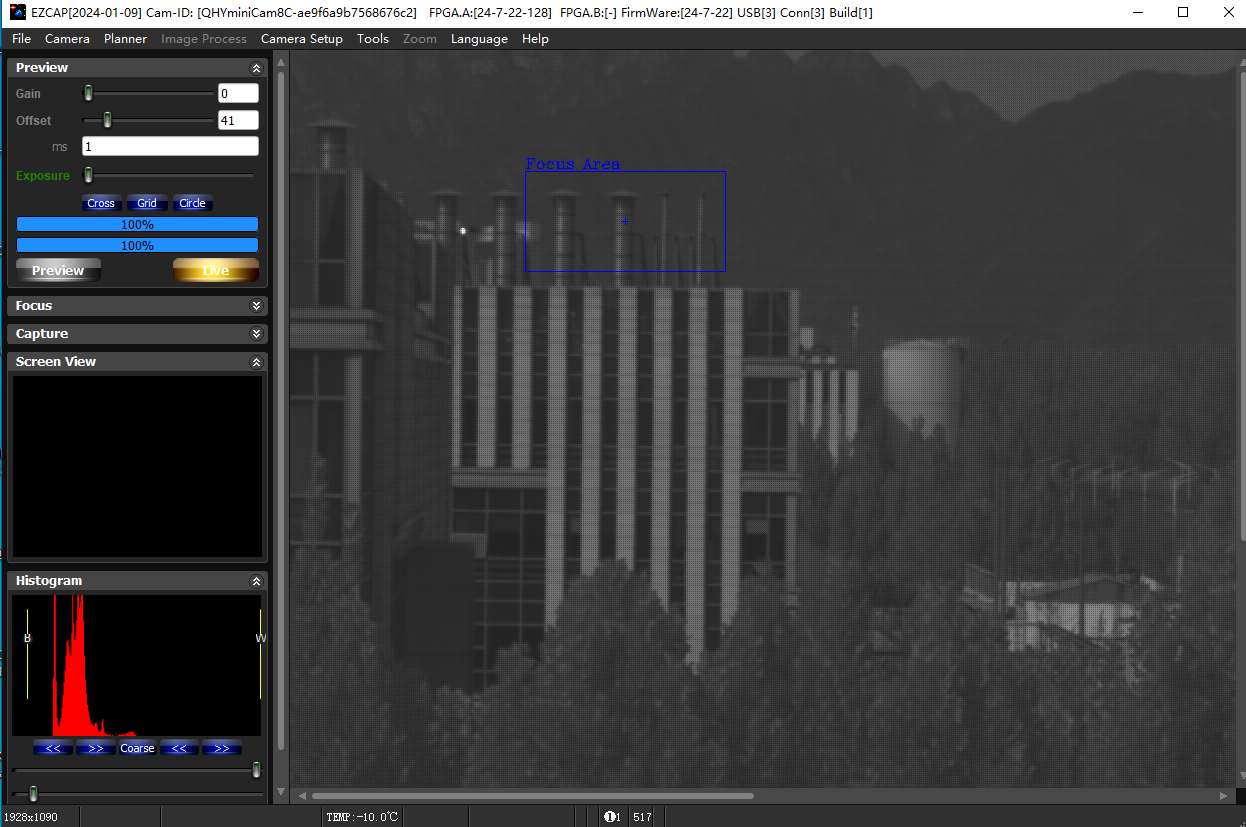

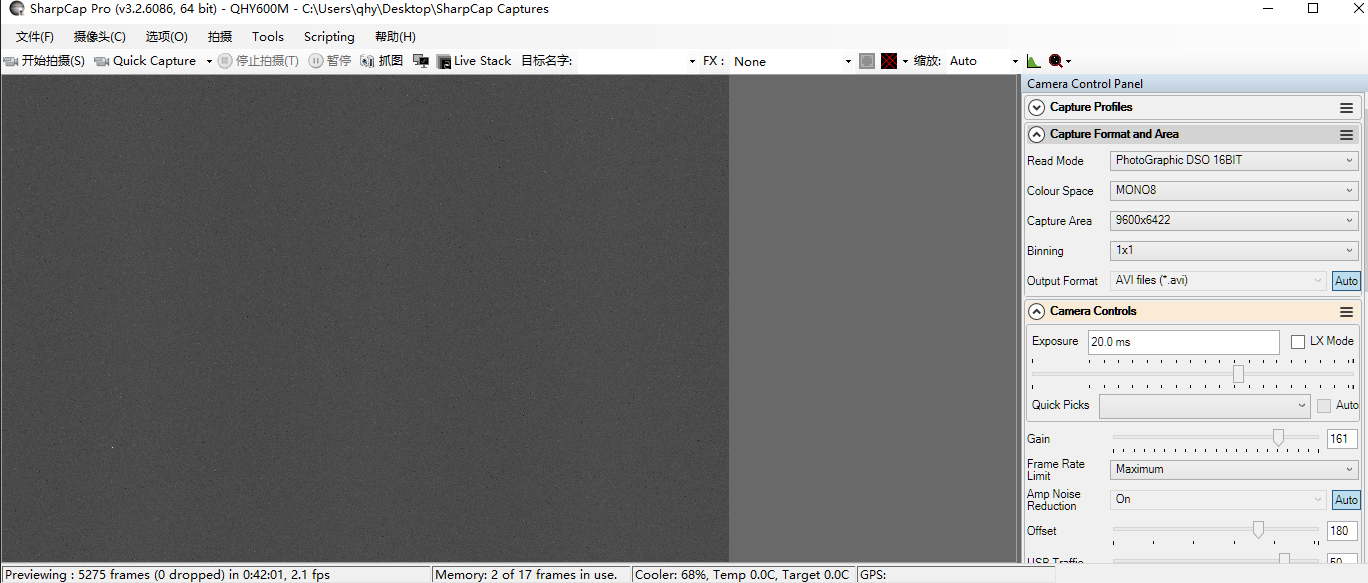

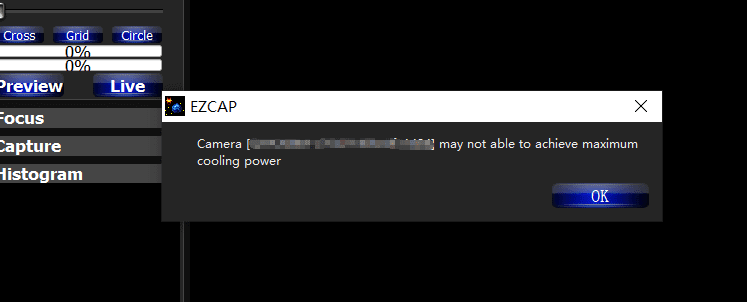

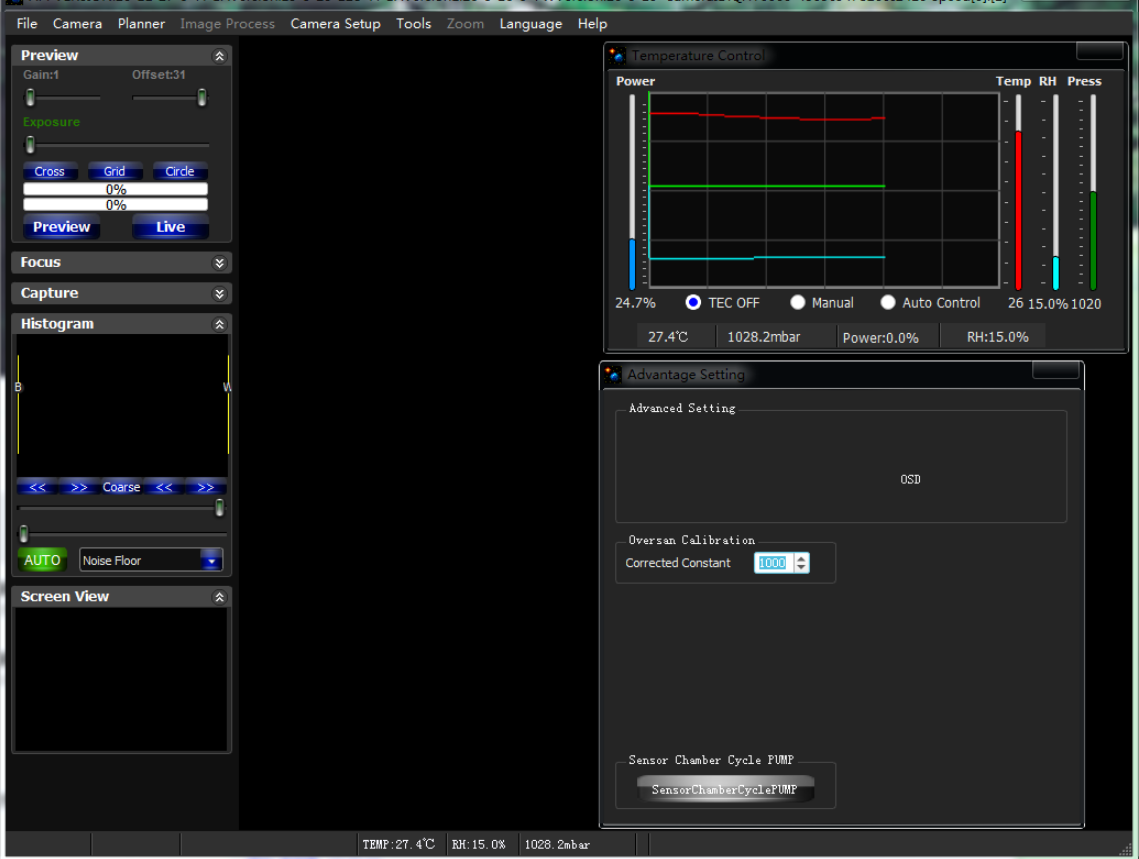

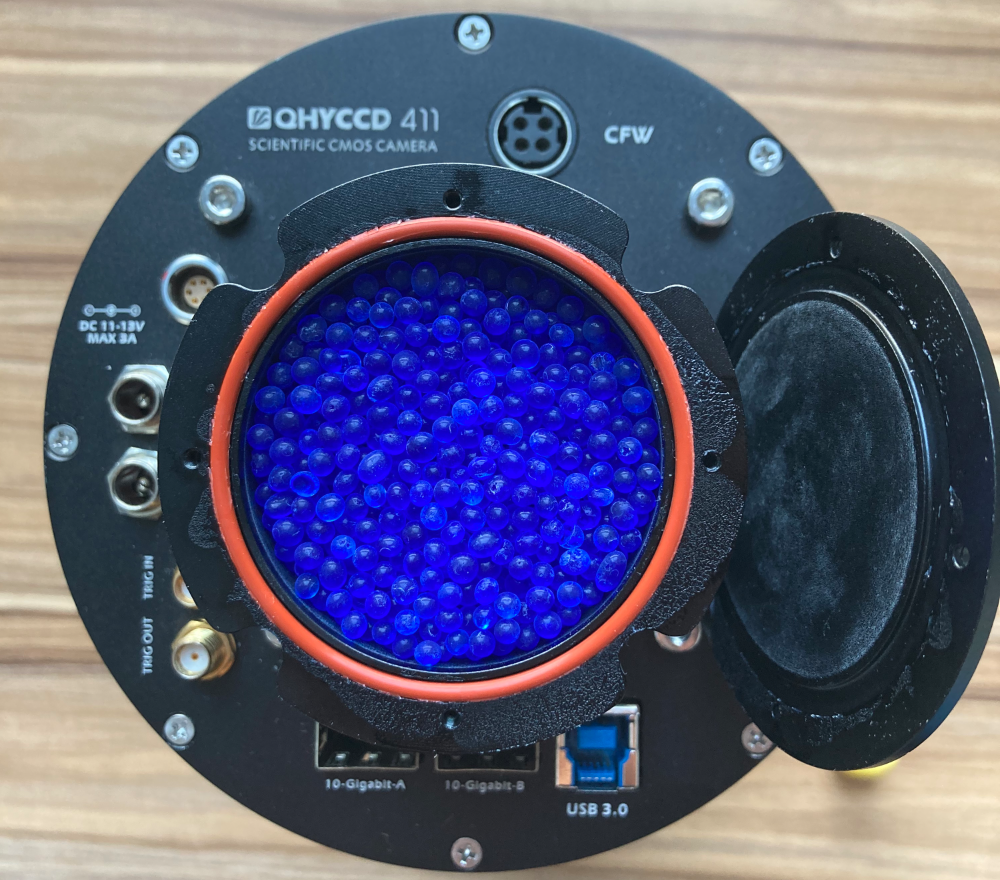

Cooling & Anti-dew Control: In addition to dual stage TE cooling, QHYCCD implements proprietary technology in hardware to control the dark current noise. The optic window has built-in dew heater and the chamber is protected from internal humidity condensation. An electric heating board for the chamber window can prevent the formation of dew.

Cooling & Anti-dew Control: In addition to dual stage TE cooling, QHYCCD implements proprietary technology in hardware to control the dark current noise. The optic window has built-in dew heater and the chamber is protected from internal humidity condensation. An electric heating board for the chamber window can prevent the formation of dew.