To Explore the Unknown Universe

WE ARE QHYCCD!

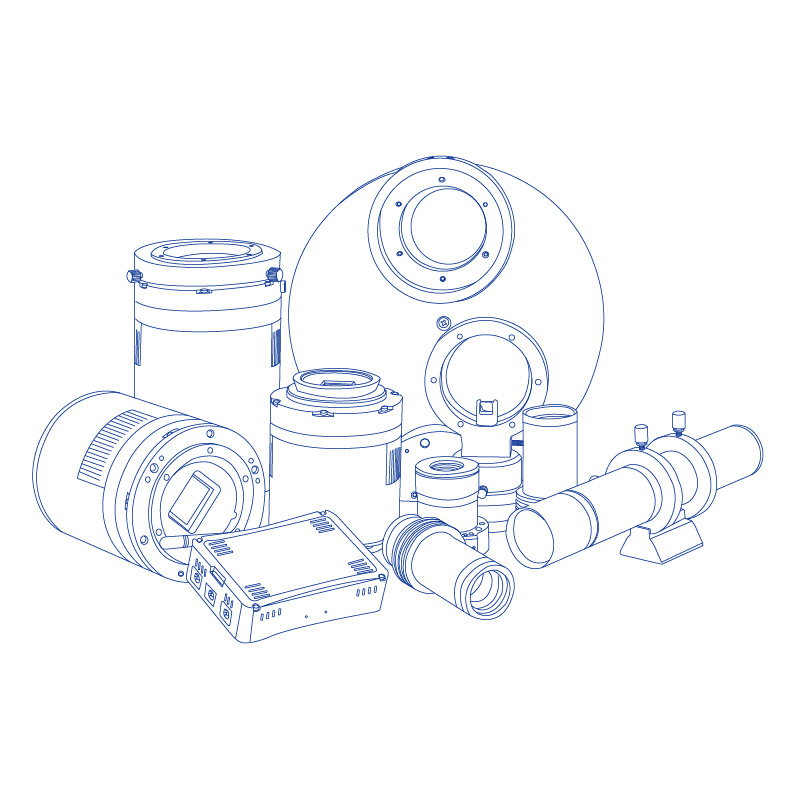

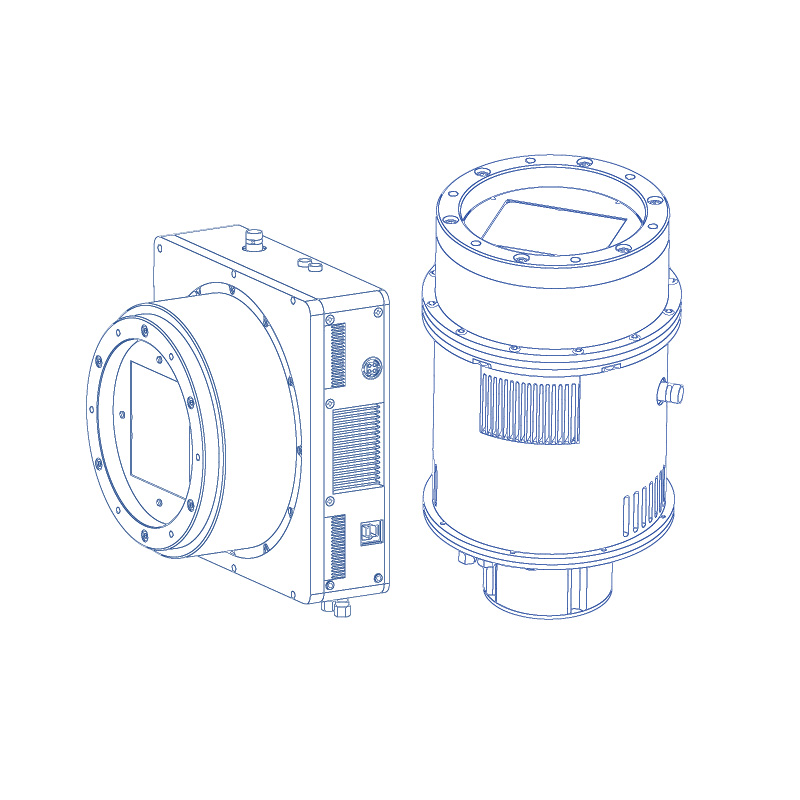

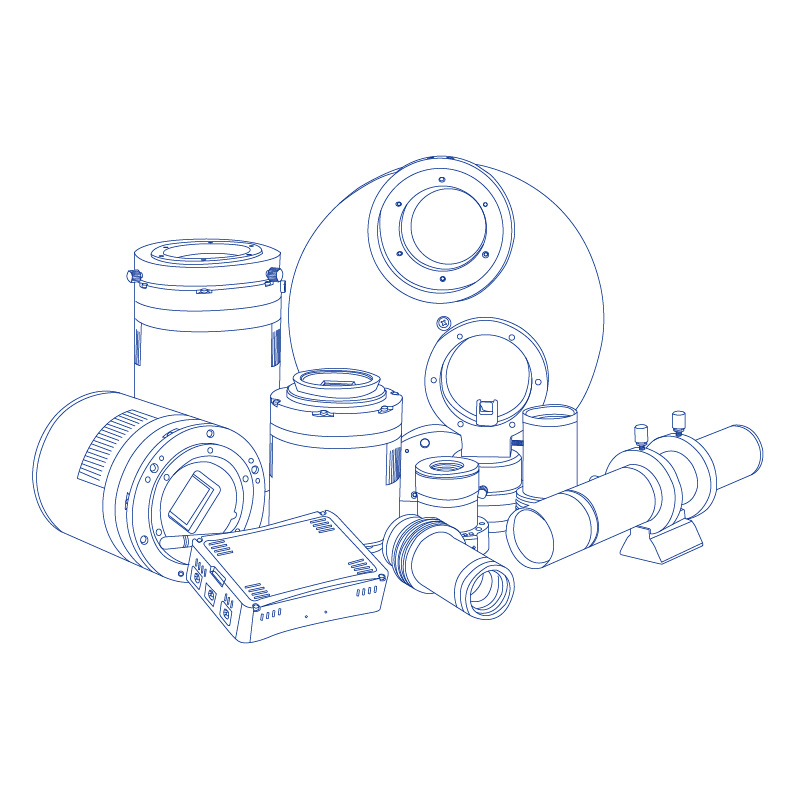

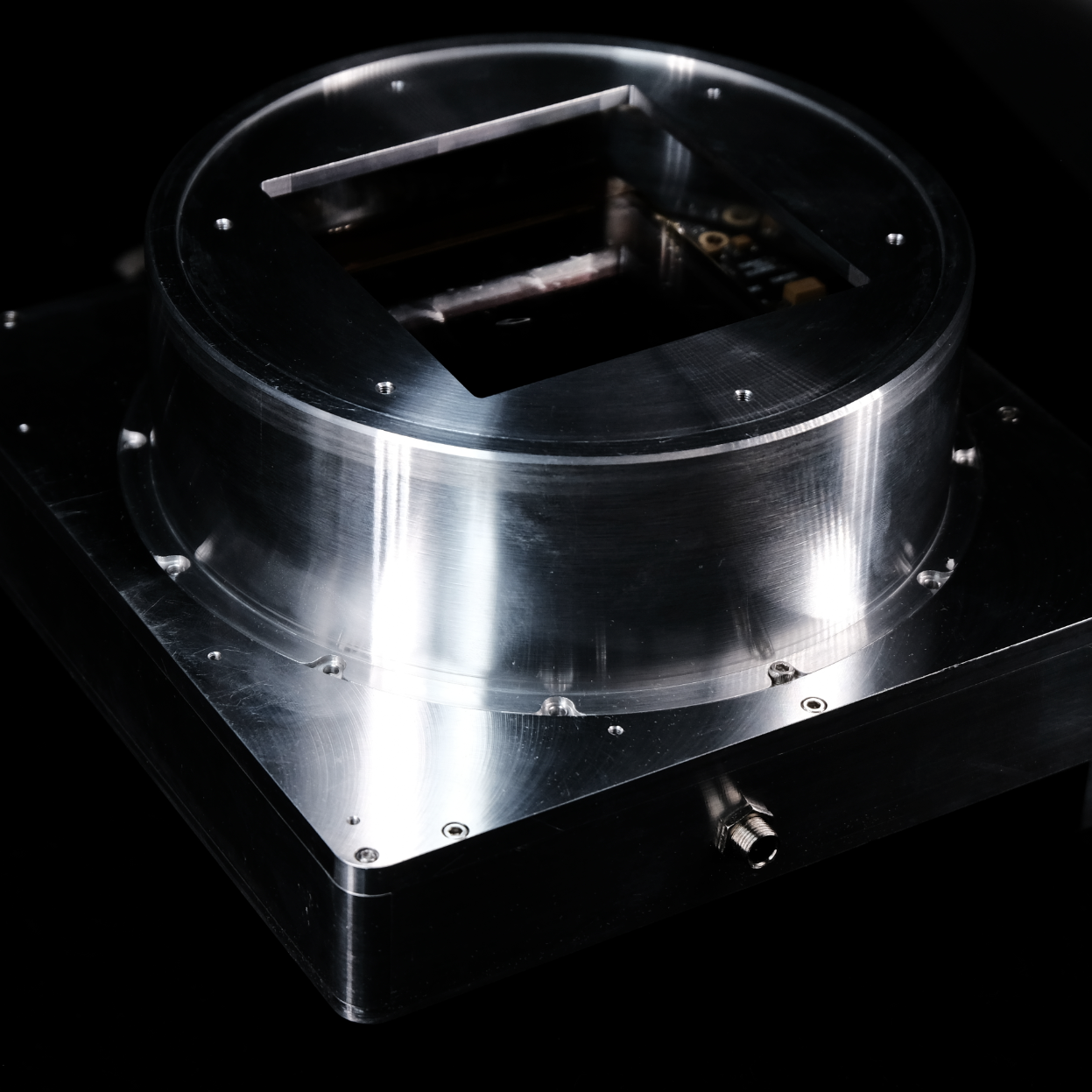

QHYCCD design and manufacture high-quality astronomy devices, including Cooled CMOS and CCD Cameras, Planetary and Guiding Cameras, PoleMaster, Focuser, etc.. QHYCCD also provide scientific cameras for astronomical researches.

Our goal is to provide the best products and services for astronomers worldwide.

Discover New Horizons

This video is made by one of our users, and images here are all captured with QHYCCD devices of different generations. We always keep moving with astronomers around the world.

APOD Collection

The Astronomy Picture of the Day (APOD) is based upon work supported by NASA under award No. 80NSSC17M0076. Each day a different image or photograph of our fascinating universe is

IOTD Collection

The “AstroBin Image of the Day ” (IOTD) is a long-running system to promote beautiful, interesting, peculiar or otherwise amazing astrophotography. Its goal is to promote the output of the

Home Page Collection

Our home page banner is left for our user’s photos! The top banner is planned to be changed every two or four weeks. You can send your works to our

AAPOD Collection

Amateur Astronomy Picture of the Day (AAPOD2) is a website and social media presence. It was built, coordinated, and edited by Jason Matter and Charles Lillo. The goal of the

Terry Hancock’s gallery

For many years, Terry Hancock imaged from his backyard, but upon retirement, he managed the Grand Mesa Observatory in Colorado, where he currently serves as Director. 【”The Golden State” Nebula

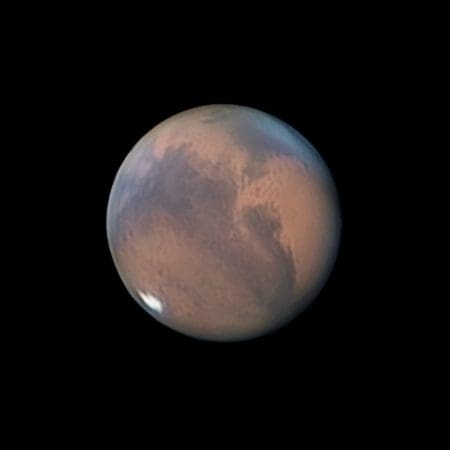

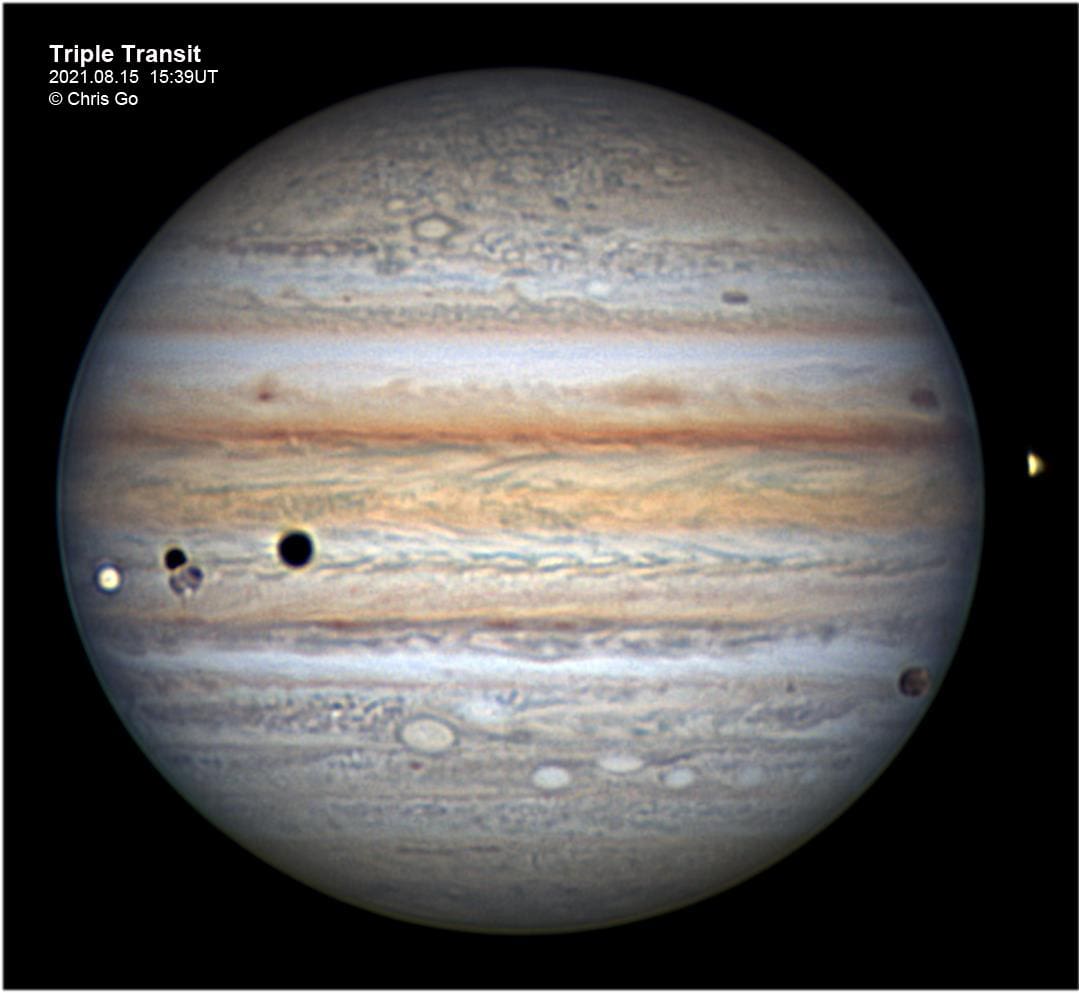

Christopher Go’s gallery

Christopher is an amateur astronomer who lives on the island of Cebu, Philippines now. In 2015, the International Astronomical Union officially designated Asteroid 2000 EL157 to 30100 Christophergo. This asteroid

Kevin Morefield’s gallery

Kevin Morefield:” Finding beauty in the night sky is my passion. Reading the works of Clark and Asimov in my youth I dreamed of what was out there in space.

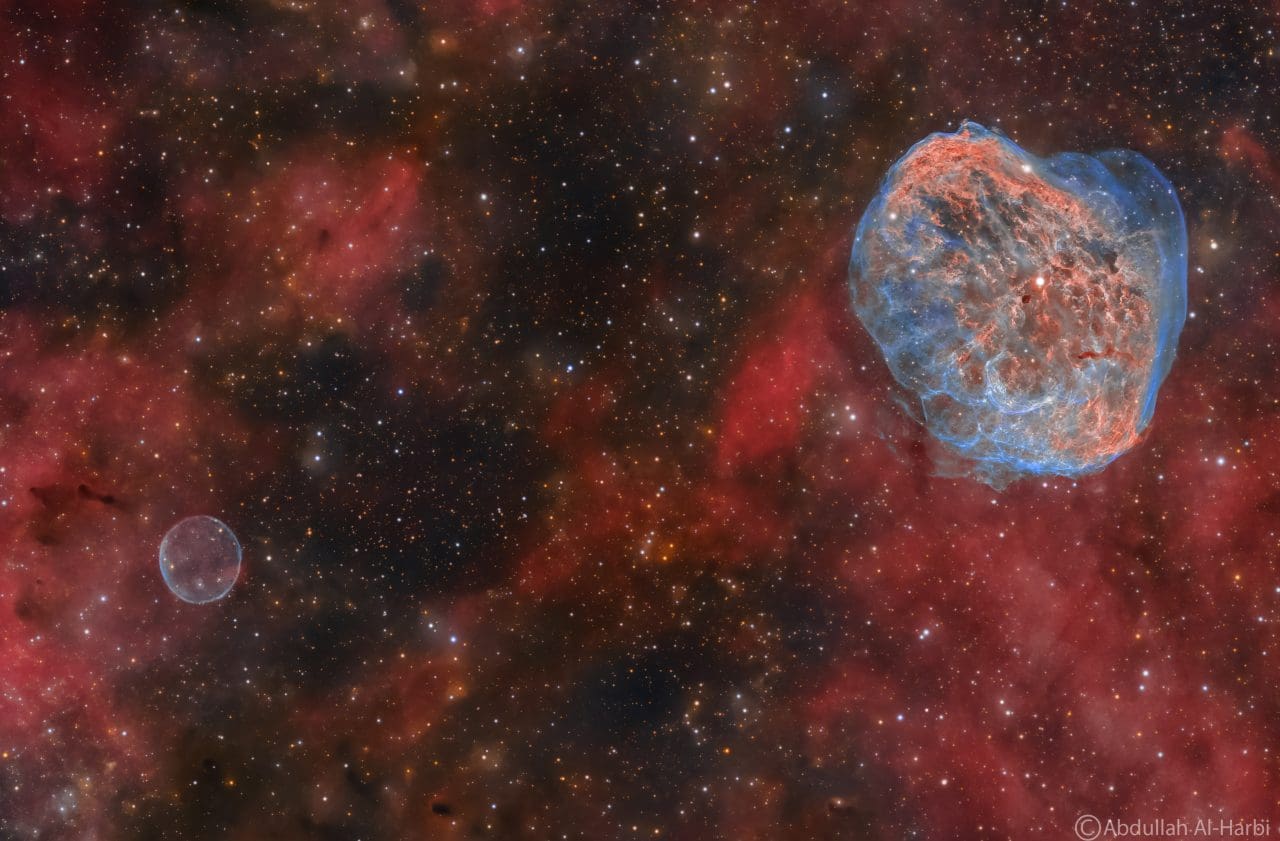

Abdullah Alharbi’s gallery

NGC 6888 and bubble soap nebula (APOD 20230904) Imaging Telescopes or Lenses: Askar 600 Imaging Cameras: QHY268M Mount: iOptron CEM40 Filters: Chroma 36mm LRGB Ha OIII Frames: Ha 300s*126

Recently Updated

DOWNLOAD

Download Driver and Manuals.

REVIEW

See Review of Astro Gears from Our Users.

HELP CENTER

Click Here for After-sale Services.